The garlic seed splitter uses a flexible rubber plate and a unique design process to make the garlic achieve the effect of artificial hand peeling. The garlic can be used in any size. The gap between the upper and lower rubber plates can be adjusted according to the size of the garlic. The gap is larger for larger garlic and smaller for smaller garlic. The separated garlic skin, garlic stem, garlic root and the soil at the root are blown away by the fan and can be collected separately. The separated garlic cloves are transported to the screening machine through the conveyor. The screening machine sorts the garlic cloves into garlic cores, small garlic cloves and garlic cloves and then bags them separately

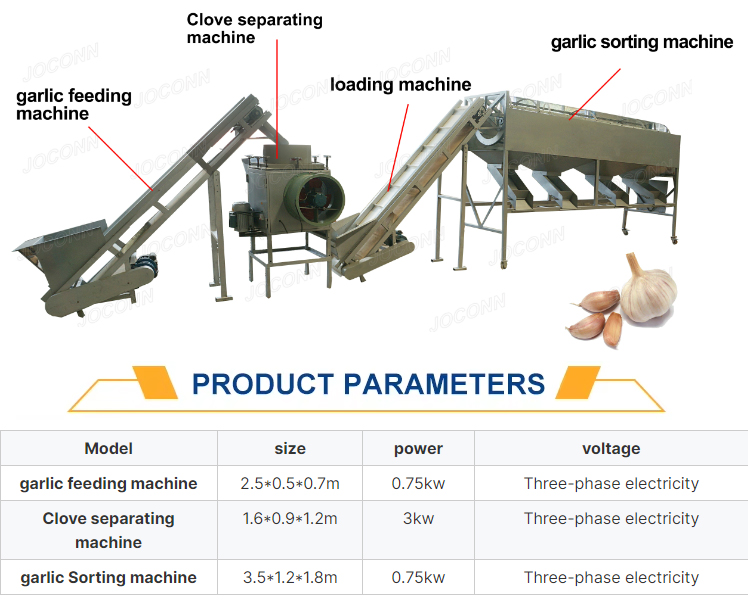

Production line:

The machines used in conjunction with the splitter include conveyors, garlic grading and sorting machines, and towing racks. These equipment can be freely combined according to customer needs and can be increased or decreased.

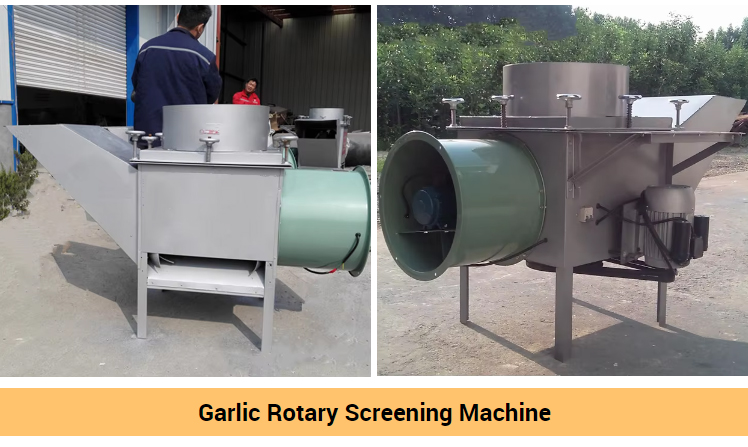

The screening machine has four outlet: 1, 2, 3, and 4:1: garlic core, small garlic roots, and soil on garlic roots; 2: mainly separates medium-sized garlic cloves; 3: mainly separates large-sized garlic cloves; 4: a few that cannot be separated are discharged from the tail discharge port, and return to the machine once after cooling for 0.5 hours.

Tel:+86 15093228930

Mobile:+86 15093228930

Email: info@agrimachinepro.com

Whatsapp: +8615093228930